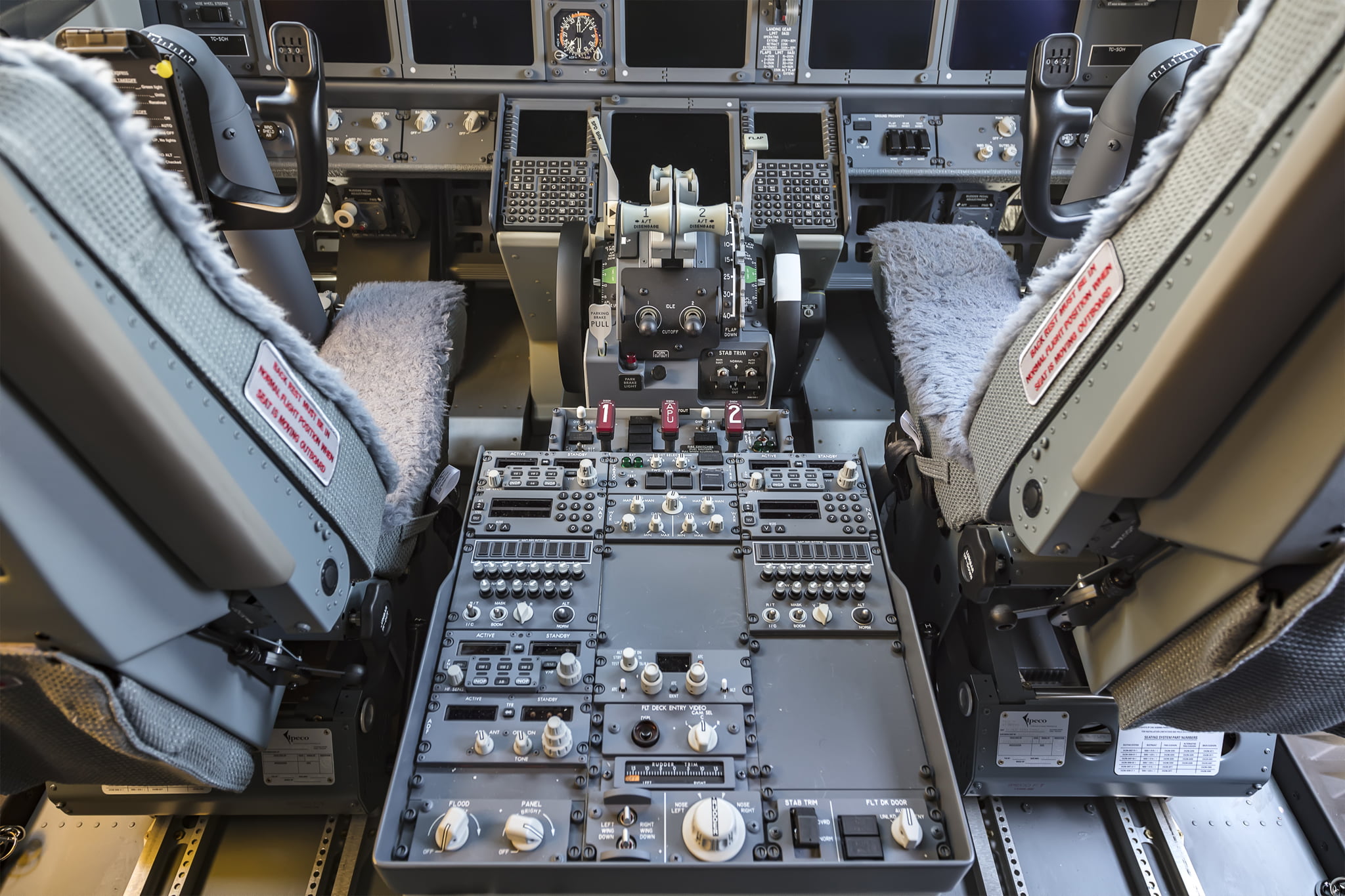

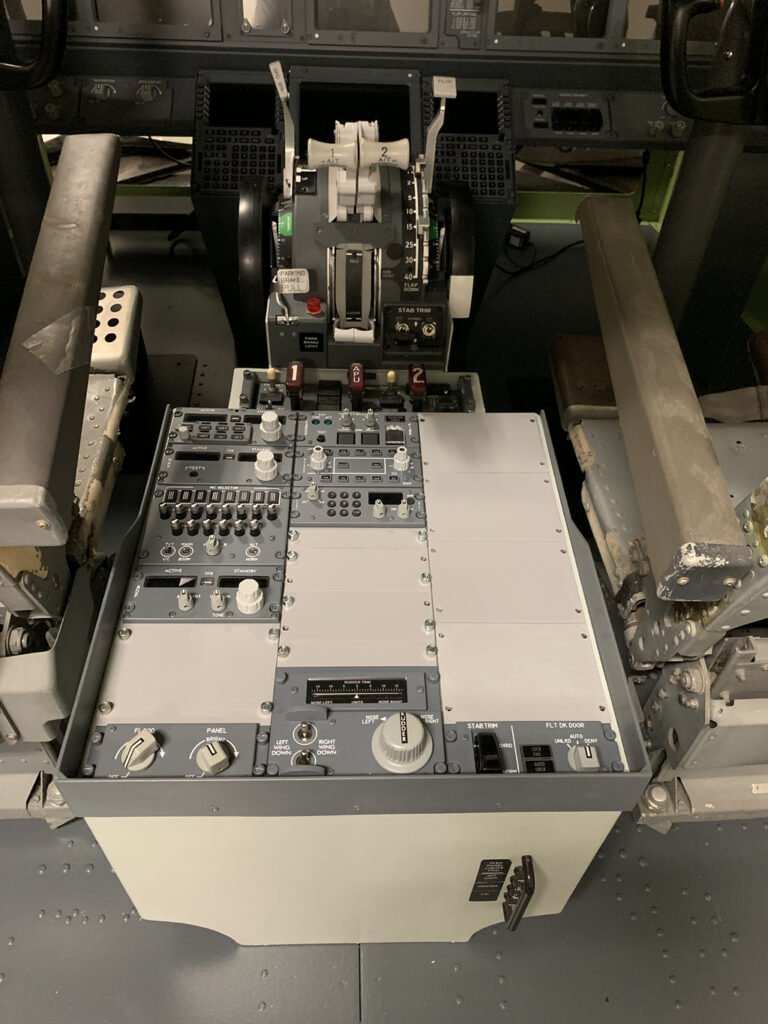

The Center Pedestal on the Boeing 737, and most aircraft, is the heart of aircraft communications. From navigation radios to weather radar, PA announcements, and even printing, this is an absolutely critical piece of equipment. It also has engine fire alerting and extinguishing systems.

Read on to find out more about my recreation of it.

What’s the Center Pedestal About?

The Center Pedestal contains the communication radios used by the pilots to communicate with Air Traffic Control (ATC), ground crews, cabin crews and more. It also holds the navigation radios to tune to navigational beacons and the Instrument Landing System (ILS) used to guide the aircraft on final approach to the runway. You’ll also find controls for adjusting the weather radar, control the transponder used to alert ATC on aircraft position and traffic avoidance, and provide some rudder trim control. Many center pedestals also contain a printer to receive communications and flight updates from the airline’s flight dispatch. And it houses the fire control panel to help alert and extinguish engine fires.

My Center Pedestal Design

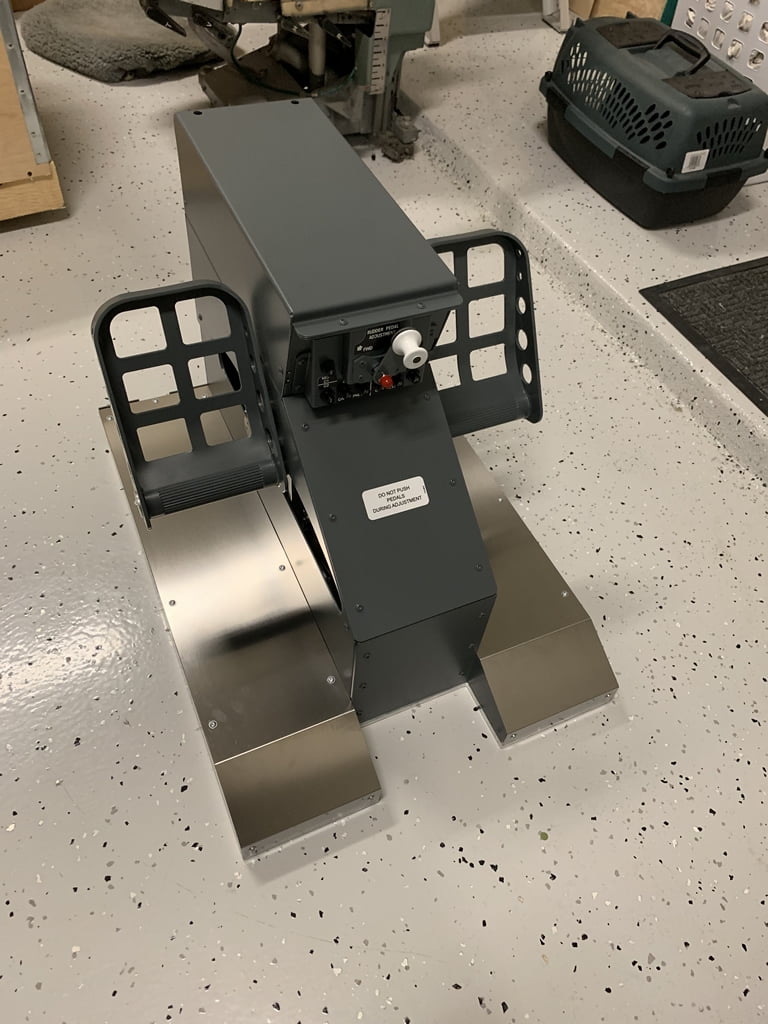

My center pedestal was built from 1/4-inch MDF wood using two-part epoxy glue. I used a router to add a nice rounded bevel to the edges.

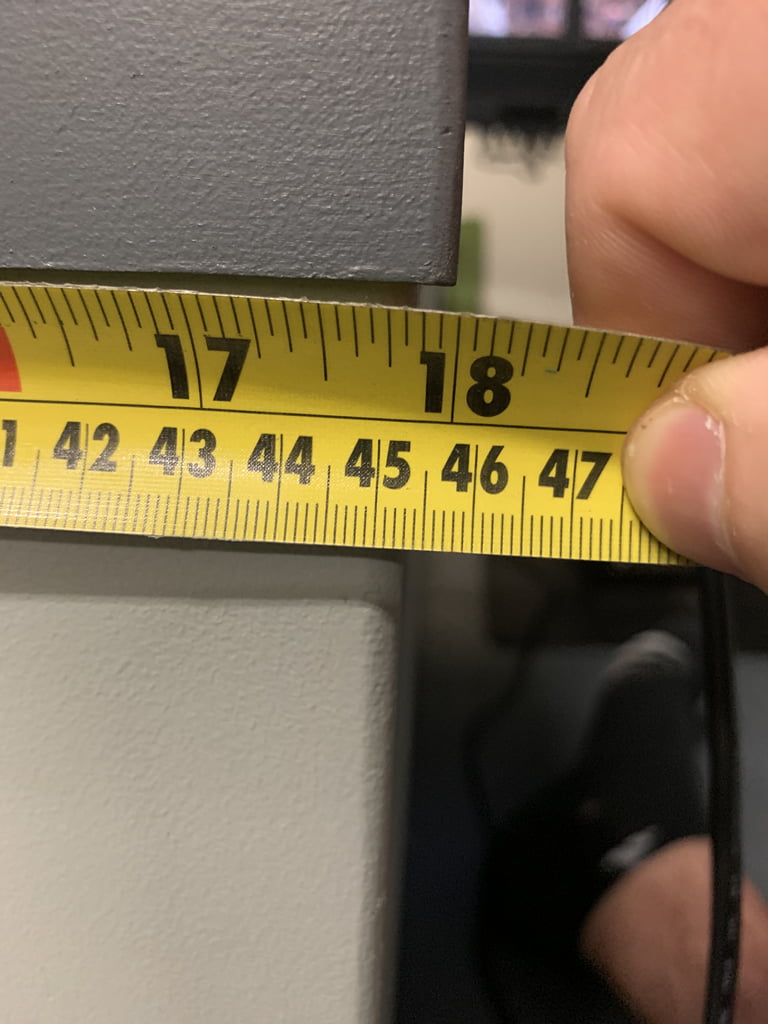

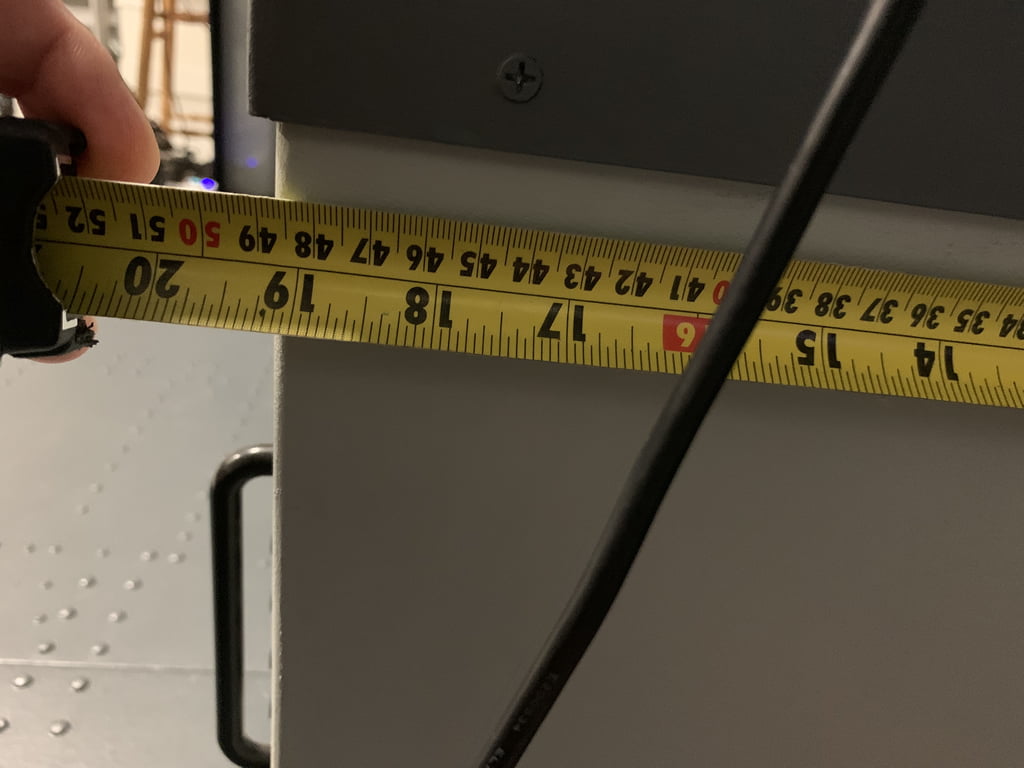

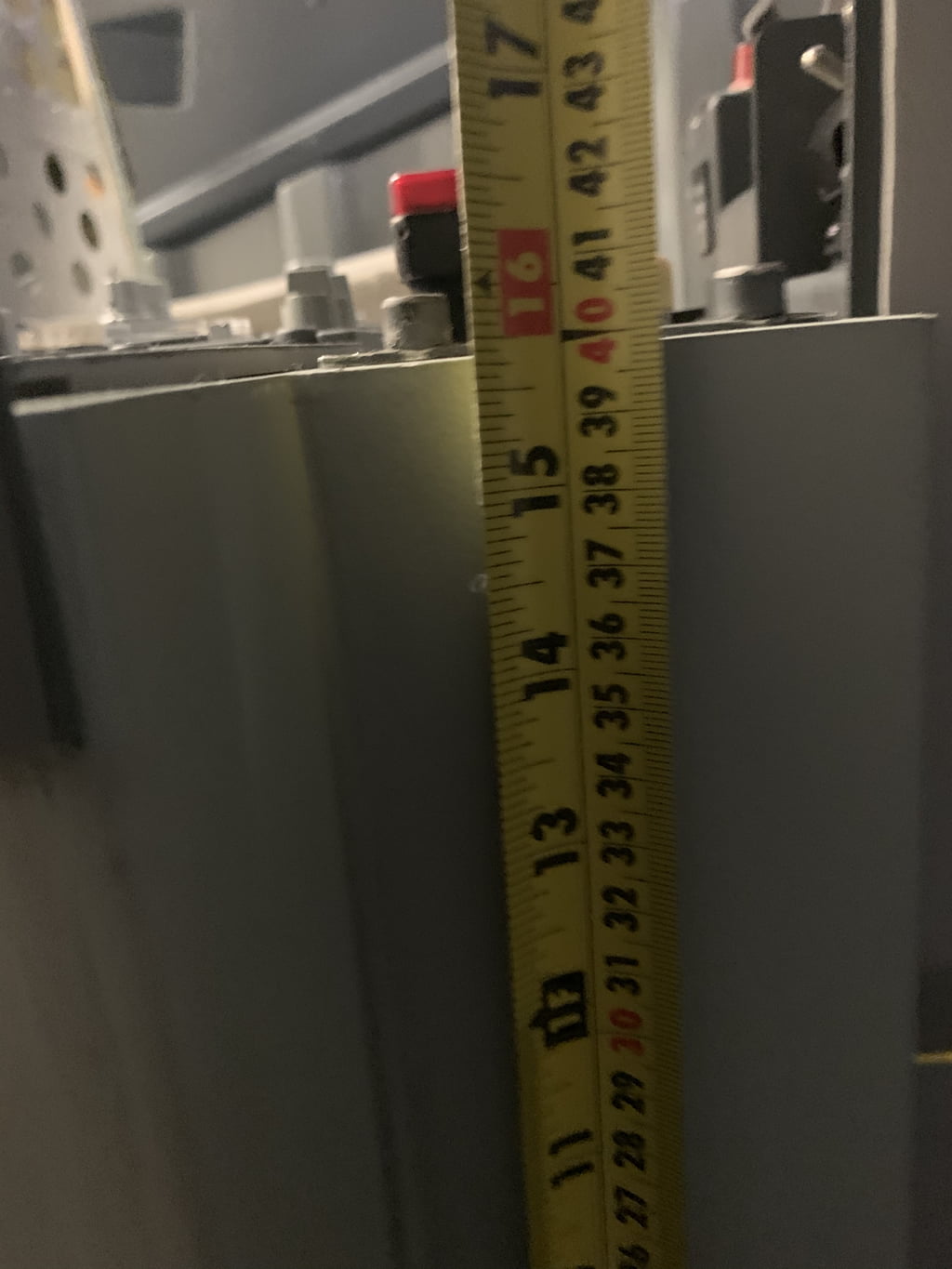

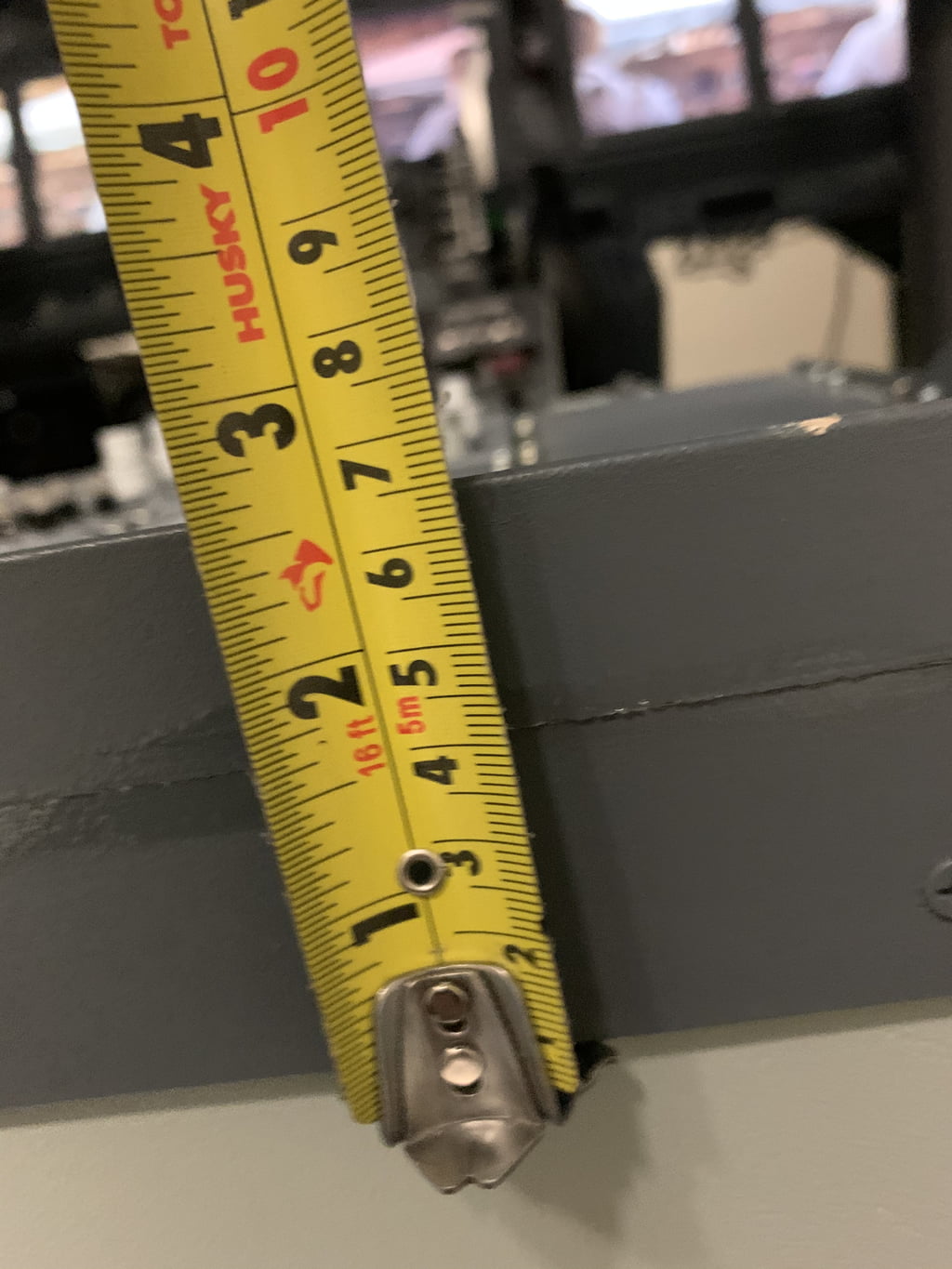

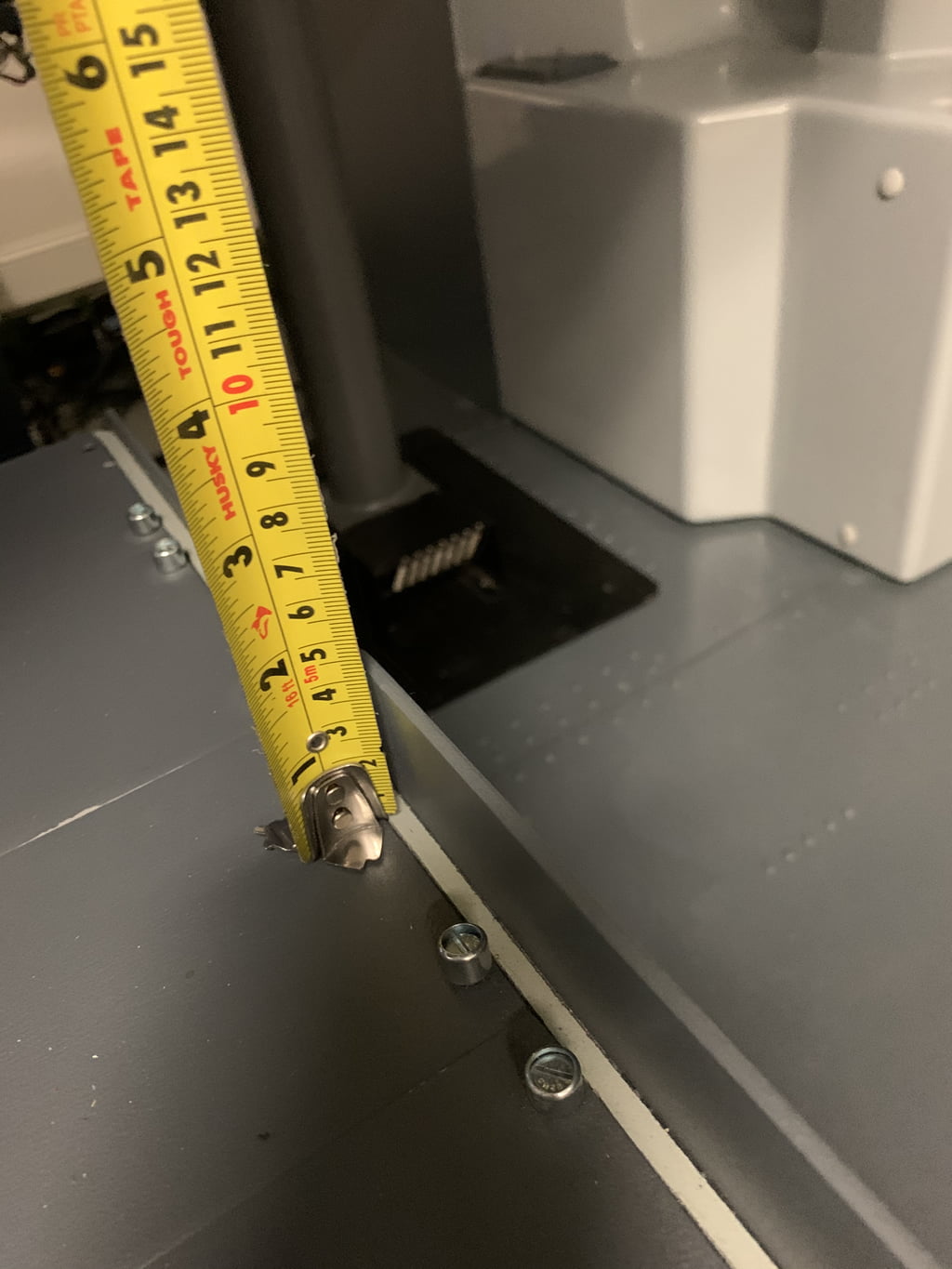

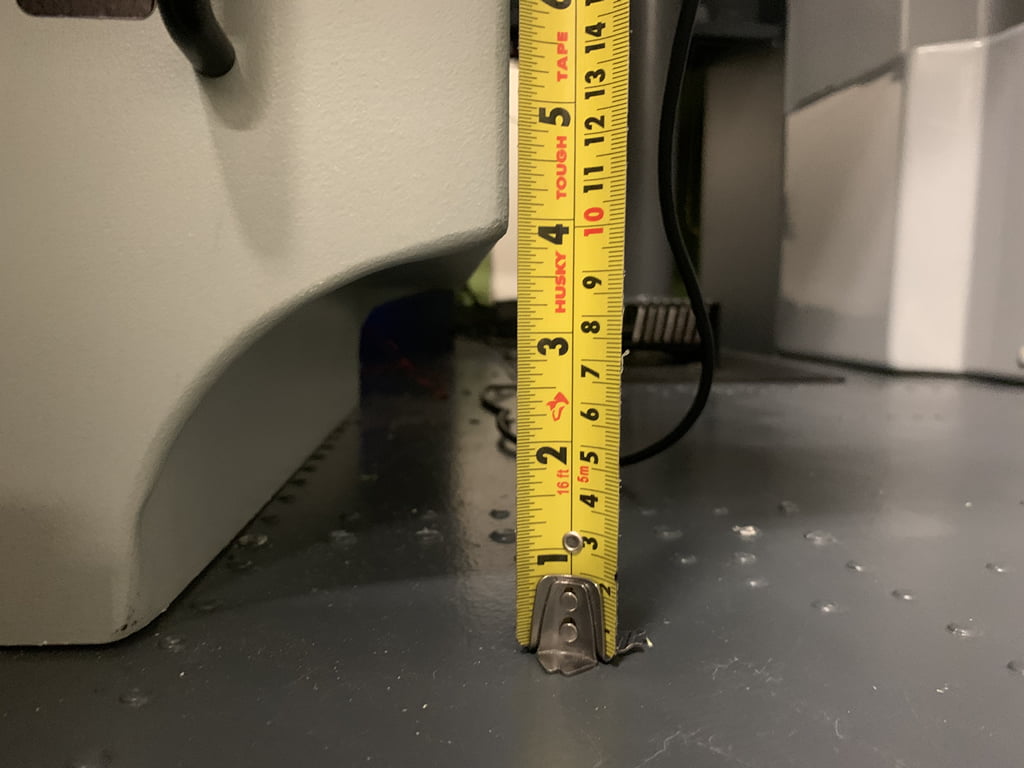

I approximated, as best I could, the correct pedestal dimensions based on measurements from sources like below:

- A very good Boeing 737 measurements reference is MarkusPilot’s 737 measurements document

- Another helpful document can be found here: http://barrytech.com/boeing/boeing.html

Here’s some photos with approximate dimensions of my pedestal for reference. Use the above references to help you refine these measurements.

Mounting Panels to the Pedestal

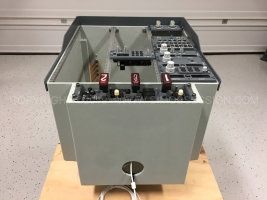

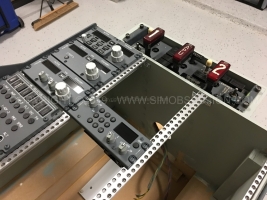

In a real aircraft DZUS rails and fasteners are used to mount the pedestal panels to the pedestal. They are aluminum right angle or “T” strips that have holes drilled at exact spacing. They also have a wire that runs beneath the rails as seen in Figure 1 below.

A DZUS screw has a special shape on the bottom to catch the wire when inserted in the hole. Turning the screw a quarter turn locks the screw onto the wire so it doesn’t come loose. This is an excellent, strong and simple design great for quick changes of equipment. All you need is a flat blade screwdriver. See Figure 1 for some fastener pictures.

Figure 1 – DZUS Rails and Fasteners

My Failed First Attempt

DZUS rails aren’t always cheap so to save money I first tried to create my own DZUS rails using wood and mimicking the hole pattern of a real DZUS rail. This proved to be tedious, difficult to drill the holes exactly, and just a waste of time.

My Do-Over that worked much better

After my dismal attempt at making my own rails I decided to bite the bullet and just use real DZUS rails. Since I use FlightDeck Solutions panels, they exactly align to the real DZUS rails like the real aircraft. Fit is therefore not a problem.

WARNING – Depending on the manufacturer of your replica panels, the panels may not be true to scale. You may find they mis-align with real DZUS rail holes. Double-check that before you go down the DZUS path. Otherwise, you may have to make your own rails. If that is the case, I’d recommend square wood dowel with some vertical supports under each rails around the middle of the pedestal to make sure it doesn’t sag. Also keep in mind the pedestal panels may not give you much room to work with if your rails are too wide.

Where to get real DZUS rails and fasteners

If you decide to buy real DZUS rails, check out Dallas Avionics where I bought mine. DZUS rails come in varying types and lengths. However, since they’re aluminum they can be cut with a metal hacksaw quite easily.

While DZUS rails aren’t inexpensive, trust me in the long run the time savings and less headaches is absolutely worth it if your panels will work with them! You can’t get any more realistic!

Keep in mind you still need to find real DZUS fasteners, so make sure the pedestal panels you buy either come with them, or can be retrofitted with real DZUS fasteners. You can find the DZUS fasteners/scews on eBay for pretty cheap.

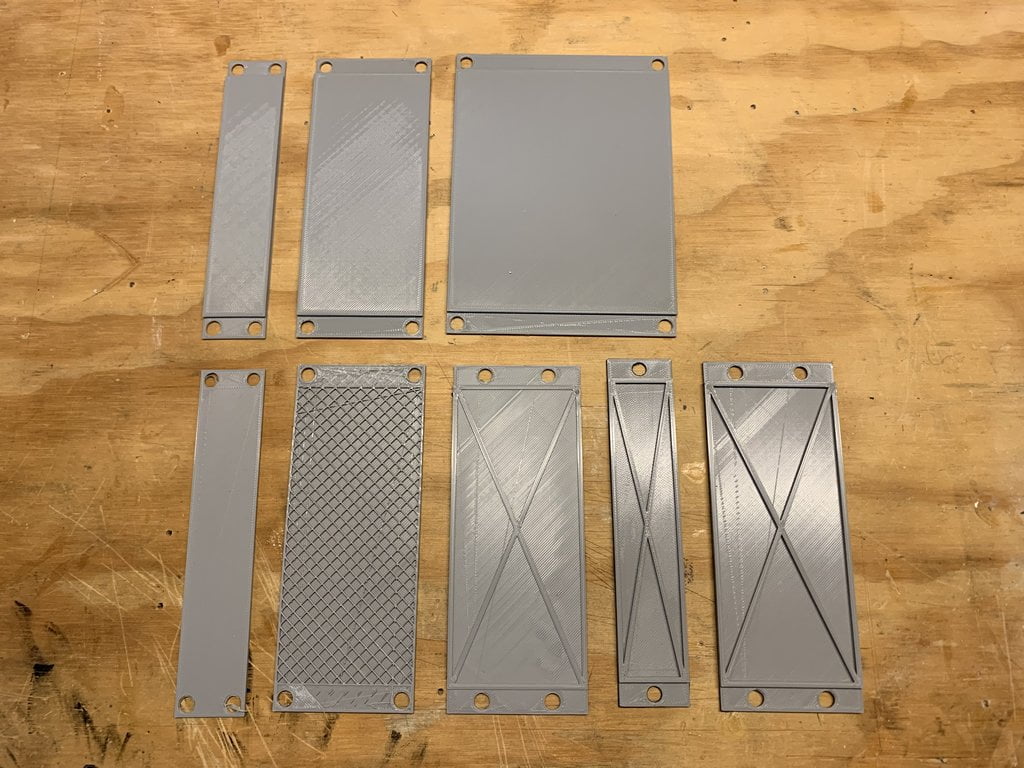

Blanking Panels

You’ll need some “blanking” panels in some areas of your pedestal where there are openings. For the blank panels I ended up designing them in the free (for hobbyists) AutoDesk360 CAD program and printing them on a 3D printer. It took some time to research the various sizes and dimensions but it’s not too hard to do. See Figure 2.

You can also buy real metal blanking plates from places like OnceAloft or from sim manufacturers if you look around. They’re not too expensive.

Electronics

Internally, I used a Phidgets relay to power on the backlighting for two sections in the pedestal. I configured one relay to trigger panel lighting for certain panels when “DC” power is switched on, per the real aircraft. I configured a second relay to turn on the remaining panels when aircraft “AC” power is switched on. Look for more information on which are which in a future update here.

I used a CPU power supply to power the 12v and 5v needed for the various panels, and a FDS SYS card to connect all the non-ethernet components into.

The pedestal is pretty cramped inside when fully equipped. Between the wires, power supplies, and interface boards there isn’t a lot of room to work with. Make sure you take your time to lay everything out properly so you don’t run a risk of shorting components out or starting a fire!

Cooling

The interior of the pedestal was generating too much heat when everything was turned on. Between two power supplies, the real aircraft bulb back-lighting on the panels, and several interface boards, I needed to cool things down.

To compensate for the excess heat, I added a small, quiet 2-inch computer fan to the bottom of the pedestal which continuously sucks the heat out. It works very well and you wouldn’t even know it’s there unless you bent over and looked closely.

Finishing Touches

To finish things off, I used an MDF primer and then latex paint from the local hardware store custom matched to the correct Boeing colors. Then I added the fake circuit breakers and guard at the rear of the pedestal with some parts from GLB Flight Products.

Future Improvements

If I were to do it again, I would use thinner material for the pedestal enclosure, like 1/8″ MDF. The 1/4-inch thick MDF is a little too thick compared to the thin aluminum used on the real pedestal.

I did goof up on the fire panel box/enclosure. I made it too wide for the real fire panel I bought. So I’ll have to go back and fix that, but no big deal. Overall I think it came out looking pretty good.

However, I think I may eventually go with a real pedestal or a purchased one. It’s very low on the priority scale at this point!

6 comments

Skip to comment form

beautiful work. you wouldn’t mind sharing your pedestal dimensipns would you. I have just started mind.

Author

Thank you. I used a lot of sources for reference. Some good ones are MarkusPilot: https://www.pdf-book-search.com/737/boeing-737-measurements-markuspilot.html. Another that may help is: http://barrytech.com/boeing/boeing-pedestal.html . Good luck!

Excellent site. Great documentation on your experience and passion for flying.

My experince is same as yours. Started out long ago with Saitek yoke, TQ, and rudder pedals. I also went the MDF route and got frustrated. I went with FDS for MIP, MCP, and Pedestal. I did buy some panels like cockpit entry lock and connected it to the FDS board.

I did buy Opencocpit panels for Overhead and connect it to a FDS SYS board. Probabaly saved me about $3K.

Sadly I dont have the room for 3 monitors. i have 2 TV monitors. TrackIR is useful if i need to look left or right.

Total investment in sim is round $30k.

Author

Appreciate the comments Steve! Sounds like a great setup. Best of luck!

Any chance you would build one for me? Let me know cost. I am a disabled USAF Veet from Desert Storm and also blind ijn 1 eye so its hard for me to do these things.

Jim

Author

Hi Jim, thanks for reaching out and thank you from the heart for your service!

As much as I’d love to help, realistically the cost and time for me to build you a center pedestal (I’m assuming that’s what you’re asking for here) would be more than what you would reasonably pay from an established company that does this for a living. I would suggest contacting CPFlight.com, OpenCockpits.com, and FlightDeckSolutions.com (they are very expensive and not offering to the public anymore, but maybe for a full pedestal they might consider). SimWorld.aero used to sell some good products but it doesn’t look like they sell to the public anymore either.

If you’re wanting to have someone build you a full cockpit, there are some additional choices, but just about all are out of Europe so shipping may be prohibitive if you’re in the U.S.

I’ll reach out to you via email in case you’d like to discuss in more detail.